Apron Conveyor Belts

Diamond Metal Screens Pvt. Ltd. undertakes all types of high precision perforation in various shapes like round, oblong, square, or dimpled. We excel in perforating conveyor belts in a variety of patterns on materials including, steel, galvanized steel, stainless steel brass, and copper. Moreover, these conveyor belts can have various types of surface coatings.

Custom manufactured perforated sheets have applications in a variety of high-end missions, like critical conveyor & transfer applications in industries like tobacco processing and food manufacturing.

Three decades of experience and other internationally assimilating technology have perfected our state-of-the-art apron conveyors. These apron conveyors provide an ideal and cost-effective solution to a wide range of materials like tobacco, desiccated coconut, fine chemicals, etc.

They also help in conveying and transferring materials through critical processing conditions, such as high-temperature steam, dry air, chemical acids, hot oils, and so on.

Apron conveyors are available in various sizes and are installed in 2 feet or a 14 feet dryer. They are used either for a dryer where gentle uniform drying is required or for the movement of heavyweight abrasive type material.

Diamond Metal Screens can manufacture these apron conveyors either in plain, perforated, or embossed type, in mild steel, galvanized steel, or stainless steel. Various types of surface coating are available to these conveyor belts.

Engineering Details

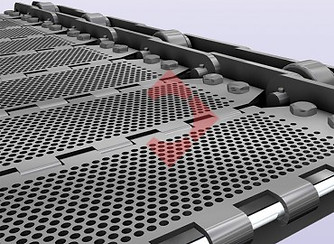

Diamond Metal Screens apron conveyors are a continuous metal belt that is custom perforated to suit the processing of the products. These perforated plates are locked in micro-mesh hinges. These micro hinge arrangements ensure a minimum gap between the plates to attain surface continuity at all times, even at slopes & sprocket area curves.

Traveling guards are the most-needed attachments of the apron conveyors. They make sure the material stays on the conveyor at all times to prevent any spillage during motion.

The robust design is known for its durability in the most critical industrial application.

For more information on the available sizes, open area requirements, do write to us.

Product Range

Diamond Metal Screens is the only apron conveyor manufacturer of the micro (piano) hinge type, in this part of the globe. Understanding the technical requirements of the end-users, we have put in our engineering and manufacturing skills to successfully produce a wide variety of apron conveyors with precise control of hole quality, pitch control, & hinge formation required for a variety of applications.

We manufacture state-of-the-art machinery that is imported from Italy, USA & Germany.

Chain Roller Arrangement

Chain roller arrangement to facilitate easy conveyance of belt systems.

Micro Hinge, Piano Hinged

Micro hinge, Piano Hinge arrangement between sheets for flexibility in motion.

Wide Array of perforation patterns

Choose from a wide array of perforation patterns & material type to suit your product & open area requirements.

Application

Diamond Metal Screens is the only apron conveyor manufacturer in formed micro (piano) hinge type, in this part of the globe. Understanding the technical requirements of end users, we have put in our engineering & manufacturing skills, to successfully produce a wide variety of apron conveyors with precise control of hole quality, pitch control, & hinge formation required for a variety of applications. Manufacturing is done on state-of-the-art imported machinery which may include perforation, leveling, radius forming, removing of bow & camber etc. Most of these machines are imported from Italy, USA & Germany.

Advantages

In comparison with the conveying system using synthetic belts, rubber belts, woven-wire mesh, etc. apron conveyors manufactured by Diamond Metal Screens have following advantages:

-

Pre-assembly at factory in sets of 5 to 10 or even more depending on the pitch of chain, thus providing value addition in terms of time required for installation. (An apron conveyor on a 12 feet wide & 200 feet long dryers has been successfully installed in 96 hours’ time.)

-

No damages to drying material.

-

High-pressure water wash or chemical wash can be given.

-

Conveyor surfaces can be treated with special coatings.

-

Energy efficient as power needed to drive is less.

-

Delivers a consistent & uniform quality product.

-

Lower maintenance cost. As low as 90% than the other designs.

-

Bad depth is held uniform throughout the conveying process resulting in an accurate & predictable drying rate with highest possible drying efficiency. “NO-GAPS” in between interconnected aprons, a problem which usually occurs in pressed slats which overlaps one another.

-

Withstands heavy impact. High height side-guards ensure bulky material movement without spillage on chain & the machine involved.